-

Processing of harvested bird’s nest.

-

Bird’s nest is processed under high temperature to remove impurities.

-

Pre-clean bird’s nest with brushes.

-

Manual impurities removal, filtering and sorting after initial cleaning.

-

Further separation of impurities from the various parts of bird’s nest.

-

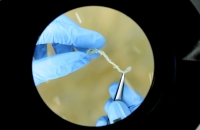

Manual select and sorting under magnification.

-

Final impurities removal, sorting and cleansing.

-

Carefully select and sort dried bird’s nest before delivery to factory.

-

Conduct quality checks on delivered bird’s nest.

-

Re-processing of bird’s nest to remove impurities.

-

Bottle is filled with BRAND’S bird’s nest soup.

-

Capping, sterilizing, packaging.

-

Quality check, storage, shipment.